1、 Equipment introduction:

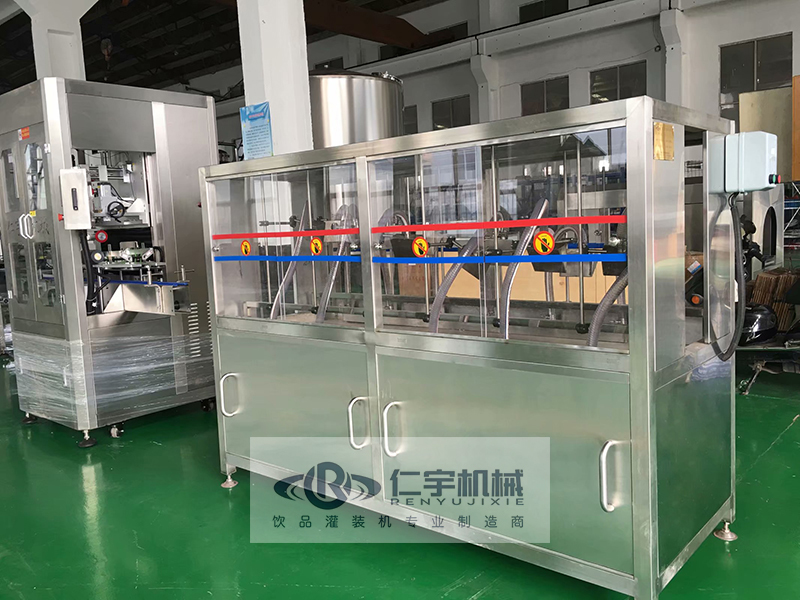

The full-automatic drying machine uses the large air volume generated by the blower to blow down/dry the water droplets outside the bottle forcefully to achieve the effect of drying, so as to prepare for the next step of code printing, labeling, labeling and other packaging. The overall structure of the air knife dryer is reasonable and simple, and the operation is simple. At the same time, the drying principle is to use the wind instead of high temperature, which is more suitable for some plastic bottles that are not resistant to high temperature. The full-automatic dryer is an ideal choice for small drying equipment. The air knife dryer is mainly composed of 11kw (two 5.5kw) vortex cyclones, stainless steel and glass frames and air knives. The double row small air knife is adopted, and the air knife can be adjusted up, down, left and right to fully ensure the drying effect. It also has strong applicability to bottles with different diameters and heights.

2、 Main technical parameters:

1. Production capacity: 10000 bottles/hour (standard) (customized as required)

2. Applicable bottle types: various round bottles, square bottles, special-shaped bottles, etc

3. Applicable bottle materials: plastic bottles, glass bottles, ceramic bottles and other bottles

4. Suitable bottle height: 160-320mm (adjustable as required)

5. Number of air knives: 2 groups (3 groups, can be multiplied as required)

6. Fan model and power: HB-5500380V, 11kW

7. Overall dimensions: 2000X800X1500 mm (adjustable as required)

8. Product weight: 450KG (about)